By Antonio Clarke and Megan Rampersaud

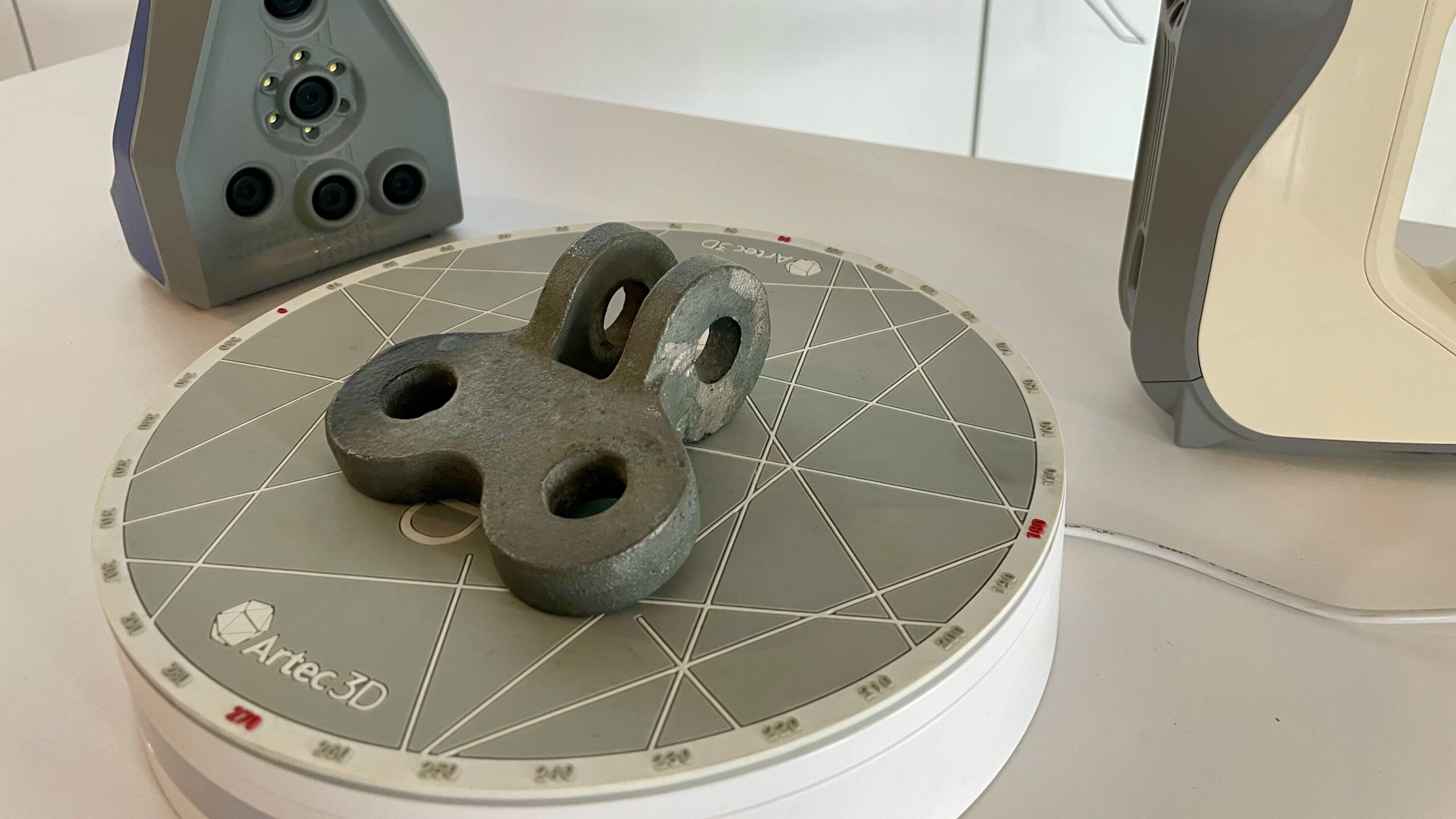

The Barrett Centre for Technology and Innovation held a workshop Tuesday to showcase how its manufacturing industry partners use 3D printing technologies to improve efficiency and costs in different industries.

One area that could see 3D scanning increasingly adopted is orthodontics.

Cory Green is the product sales specialist at the software company TriMech and oversees many of its operations.

Green explained during an interview with Humber News how 3D-scanning could be used to change dental retainers based on teeth and jaw movements specifically for Invisalign retainers.

“We want people to understand that there are two main uses for 3D scanning, one is designing things from the data that you scan, and inspecting the parts that you’ve built from your scan data,” he said.

The technology also lets manufacturers scan their materials to check for quality, and durability and even ensure parts are the proper size, helping to save time and cutting material costs.

Richard Martens and Mihir Mistry, who work for the steel industry company Voestalpine, attended the workshop and said the information was informative and beneficial for their company.

“We’re doing post-manufacture inspections so this software gives us the ability to also take some physical components, be able to translate it back into software, and reproduce or modifying it makes it much easier,” said Mistry, Additive Manufacturing Technician for Voestalpine.

During the workshop Green talked about how the show Saturday Night Live worked with TriMech to 3D scan guest host’s faces, creating prosthetics for the makeup department.

That caught the attention of Maria Perez, a second-year media and communications student at Guelph-Humber who attended the workshop with her father who is in the industrial industry.

“When they started talking about Saturday Night Live and when they have to scan an actor’s face – that’s something that got me interested because this helps to reduce the struggles with scanning technology,” Perez said.

Paul Sesto is the Client Executive for TriMech and explained in the presentation that its goal is to work with both top-name companies and smaller companies.

Sesto said during the workshop that TriMech works with various industries such as automotive, consumer products, and even hospitals.

The company helped SickKids improve its hospital rooms by scanning critical care units.

Green explained during the presentation how reverse engineering technologies benefited chemical fridge container companies in Ontario.

Reverse engineering involves scanning physical products to provide data allowing workers to modify or quickly re-create a design or part.

Companies that are longer distances from each other, can now quickly re-create the container, modify, or make improvements – saving time and materials.

While 3D scanning and printing has evolved quickly over the years, Green said the next step for TriMech is to possibly have AI work in tandem to complete scanning and process faster.

As TriMech considers this move, Cory Green understands that it could also become pricey in the future.

“No one does reverse engineering for free,” he said.